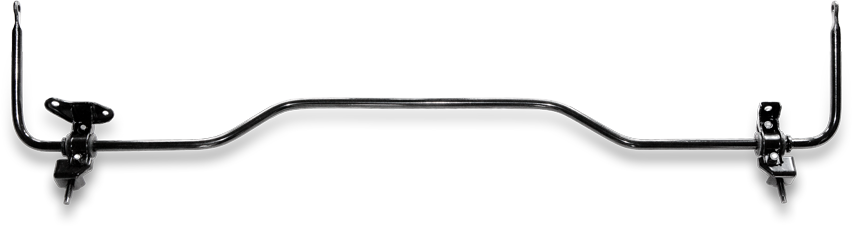

Solid Stabilizer Bars

Our unique manufacturing technologies combine features such as anti-lateral collars and non-slip bushings for reduced clearances to adjacent components. Our class-leading engineering processes offer the capability to analyze all the unique shapes and deflections common in stabilizer development using our internally developed FEA software and employ validation testing to confirm performance.

Tubular Stabilizer Bars

Tubular stabilizer bars can generate typical mass reductions of 40% relative to bars of solid construction. Our combination of custom steel grades and unique quenching systems support the demanding fatigue performance of your most-demanding applications. We also employ unique forming technology to reduce stress in critical bend areas.

Bonded Bushing

With class-leading designs in bonded bushing production applications, our bushing applications are highly-durable with a rubber-to-stabilizer bond designed for no separation during life of the stabilizer bar system. We also offer unique design and assembly capabilities for the supply of no-slip compression bushing assemblies.

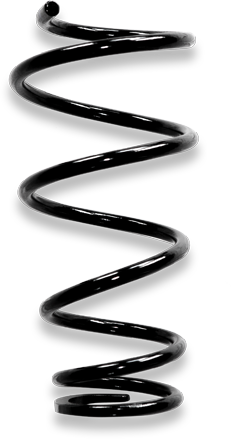

Shaped Coil Springs

Our shaped, hot-wound coils offer our customers a wider range of spring load and rate capacity, tight index capability, low mass / high efficiency with tapered bar and more consistent pitch relative to other manufacturing methods. With our V-shape technology, MSSC springs accommodate side load and pierce point requirements of strut applications and afford custom shape for unique geometry applications.

Conical Coil Springs

Our tapered bar diameter capabilities offer stress leveling in regions of the coil body that do not require a large bar cross section and afford reduced packaging space. We also use proprietary micro-alloy steel grades to accommodate higher stresses which equates to lower mass in our springs. All of our manufacturing lines incorporate warm double peen technology to generate elevated residual stress levels at the spring surface resulting in higher fatigue performance.

Torsion Bars

We're the largest producer of torsion bars in North America with exclusive manufacturing in our Chatham, Ontario facility. Our torsion bars can provide the perfect compromise offering the performance characteristics of a coil spring with the significantly reduced vertical height packaging for your specific design requirements. We can provide unique finishing solutions as well as make use of micro-alloy steel to reduce mass and packaging.